3M adhesive transfer tape double-sided 467MP 250x180mm

The 3M 467MP adhesive is an industrial transfer adhesive that was developed for special industrial applications. The main application is bonding in connection with materials made of metal. As a transparent adhesive, its use ensures the unrestricted reproduction of the optical properties of all transparent materials. As an adhesive without a carrier, it is therefore particularly suitable for ensuring the legibility of labels clearly and without any loss of transparency on carrier materials.

This product can be used quickly and easily.

The prerequisite is clean and dry material surfaces. If this is ensured, the bond can be implemented immediately under the greatest possible pressure. The high initial adhesion of the adhesive supports the success and quality of the joining process. To ensure the required clean surface quality, it is advisable to always clean the affected areas beforehand with a grease-free solvent.

Thanks to its features, the adhesive can also be used successfully on materials with low-energy surfaces. For example, with components made of polyethylene or polypropylene.

The reference value for the adhesive force is 55 N / 100 mm on metal (stainless steel, aluminum). The temperature resistance ensures all normal operating conditions between - 40°C to + 95°C. This also applies to the adhesion resistance under the influence of chemical compounds such as fats, oils, or salts.

Extensive specifications enable the adhesive to be used under defined quality standards in various branches of Industry.

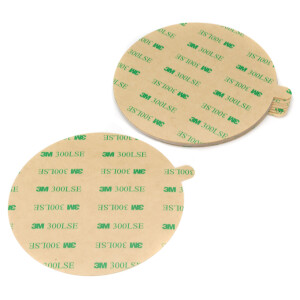

The adhesive is available in other versions as part of a product series. There is thus the possibility of optimizing the shape and dimensions of the adhesive, tailored to requirements.

Characteristics:

- super strong 3M pure acrylate adhesive 200 MP

- transfer tape without backing

- protective paper siliconized on both sides and coated with polyethylene

- climate resistant

- UV-resistant

- water resistant

- temperature resistant

- transparent glue

- extremely long shelf life

- easy removal possible

Scope of delivery:

- 1 sheet of 3M 467MP transfer adhesive

Dimensions:

- Width: 180 mm

- Length: 250 mm

Applications:

- suitable for electronics, household, medicine, automotive and aircraft sectors

- self-adhesive finishing of signs, front panels, labels, etc.

- for bonding foam and powder coatings

Specifications

The 3M 467 MP product:

- meets the MIL 19843 standard

- BUL approved under file number: PGGU2.MH26206 for indoor and outdoor applications

- AGA and CGA recognized

- Fulfills the delivery conditions of the Keyboard Association (FT)

- meets automotive industry specifications.

The manufacturer's quality assurance system is ISO 9002 certified.

Adhesion:

- Metal (stainless steel, aluminum): 55 N / 100 mm

Relative humidity:

High relative humidity does not affect the adhesive's performance. After exposure to 90% relative humidity for 7 days at a constant temperature of + 32°C, the bond values ??are generally higher than at the beginning of the bond.

Resistance to water:

If the adhesive bond remained in water at + 22°C for 100 hours, there was no change in the adhesive values.

Permanent temperature resistance:

The transfer adhesive is durable from - 40°C to + 95°C. For a short time (up to 1 hour) the adhesive connection can be loaded up to + 150°C.

Resistance to temperature changes:

The adhesive values ??generally increased when the following temperature change cycle was carried out four times: 4 hours + 70°C; 4 hours - 29°C; 16 hours + 22°C.

Chemical resistance:

When properly bonded, the adhesive connections are resistant to most mineral oils, greases, fuels, aliphatic solvents, weak acids, salts, and alkalis such as gasoline, kerosene, JP-4fuel, lubricating grease, etc.

Processing information:

To achieve a good bond, the material surfaces to be bonded must be dry and clean. For cleaning, grease-free solvents such as n-heptane or isopropyl alcohol is recommended. When gluing, the highest possible pressure should be exerted and a temperature of at least + 4 ° C should prevail. The higher the pressure and temperature, the better the adhesive penetrates the pores of the substrate and the higher the adhesive values ??that can be expected.

When unwinding the roll, we recommend the use of a guide roller to avoid missing spots during lamination. The adhesive should be peeled off over the smallest possible angle.

Processing example:

The tape must be cut to size accordingly before bonding

1. Clean the surface

2. Press the adhesive tape on firmly or roll it

3. Peel off the paper layer of the adhesive tape (adhesive film remains on the surface)

4. Connect the materials to one another and press them on

Average product review

You need larger quantities of adhesive tapes, customized products, or need consulting?

Mon-Fri 8:00 a.m. - 2:00 p.m.