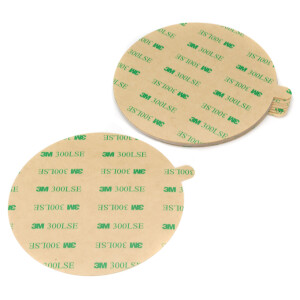

3M adhesive transfer tape 9495LE D80mm 10pcs

The unique 3M 9495 adhesive tape is ideally suited for all areas of application in which a particularly high initial adhesion is required, and permanent adhesive strength must be achieved on a wide variety of materials. The innovative LE 300LSE has the right adhesive which, thanks to many years of development work and experience, meets all these requirements and achieves the best results in terms of adhesive force. This applies above all to different metals such as stainless steel or aluminum, but also to high and low-energy surfaces of all common plastics such as ABS or polypropylene. This covers all common everyday surfaces as far as possible. The adhesive is therefore very suitable for use on touchscreens, digitizers, glass panes or mobile phone displays.

This reliable adhesive can also be used with high-quality devices and without fear of occurring damages while peeling off. The universally applicable adhesive tape can be cut to size according to individual requirements and can be used for common touchscreens from all well-known manufacturers such as Apple, Samsung, Sony, LG, HTC, and many others.

Waterproof and UV-resistant, this adhesive tape is not only used in the electronics sector, but above all in the household, in the automotive and aircraft sectors and even in the medical sector. The tape can be used to produce self-adhesive holders easily and efficiently for signs or printed front panels, but also labels. Even at very high temperatures or strong temperature fluctuations, the adhesive tape does not lose any of its outstanding adhesive strength and can be easily removed, if necessary, despite its strong adhesion.

Characteristics:

- super strong 3M 300 LSE adhesive

- transfer tape without backing

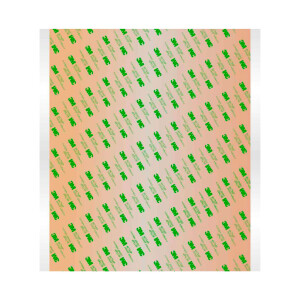

- protective paper siliconized on both sides and coated with polyethylene

- climate stable

- UV-resistant

- water resistant

- temperature resistant

- to assemble glue for every cell phone model

- transparent

- extremely good durability

- easy removal possible

Applications:

- digitizer

- suitable for electronics, household, medicine, motor vehicles and aircraft.

- self-adhesive finishing of signs, front panels, labels, etc.

- especially on low-energy surfaces such as B. polyethylene and polypropylene

- for bonding foam and powder coatings

- for connecting the touchscreen display to the housing

Adhesion:

- Metal (stainless steel, aluminum): 23 N / 25 mm

- Material with high-energy surfaces, e.g., ABS: 21 N / 25 mm

- Material with low-energy surfaces, e.g., polypropylene: 21 N / 25mm

Features and benefits:

The following performances and properties are based on tests with sign materials such as B. aluminum, glued to stainless steel.

Relative humidity:

High exposure to relative humidity does not affect the adhesive's performance. The bond values ??are generally higher after exposure to 90% relative humidity for 7 days at a constant temperature of + 32°C than at the beginning of the bond.

Resistance to water:

A 100-hour storage of the adhesive connection in + 22°C warm water does not lead to any change in the adhesive values.

Permanent temperature resistance:

The transfer adhesive can be subjected to permanent loads from - 40°C to + 95°C; for a short time (up to 1 hour), the adhesive connection can be subjected to loads of up to + 150°C.

Resistance to temperature changes:

The adhesive values ??generally increased when the following temperature change cycle was carried out four times: 4 hours + 70°C; 4 hours - 29°C; 16 hours + 22°C.

Chemical resistance:

When properly bonded, the adhesive connections are resistant to most mineral oils, greases, fuels, aliphatic solvents, weak acids, salts, and alkalis, such as gasoline, kerosene, JP-4fuel, lubricating grease, etc.

Processing information:

To achieve a good bond, the material surfaces to be bonded must be dry and clean. For cleaning, grease-free solvents such as B. n-heptane or isopropyl alcohol is recommended. When gluing, the highest possible pressure should be exerted and a temperature of at least + 4°C should prevail. The higher the pressure and temperature, the better the adhesive penetrates the pores of the substrate and the higher the adhesive values ??that can be expected.

When unwinding the roll, we recommend the use of a guide roller to avoid missing spots during lamination. The adhesive should be peeled off over the smallest possible angle.

Processing example:

The tape must be cut to size accordingly before gluing.

- Clean the surface

- Press the adhesive tape on firmly or roll it

- Peel off the paper layer of the adhesive tape again (adhesive film remains on the surface)

- Connect the materials to one another and press them on

The products of the adhesive series 300 LSE can be classified as permanent, low temperature and special adhesives (PNS) (according to DIN 30646).

Average product review

You need larger quantities of adhesive tapes, customized products, or need consulting?

Mon-Fri 8:00 a.m. - 2:00 p.m.