Sanding sponge & sanding pads

Sanding fleece, sanding pads and sanding sponges for wood, metal, plastic and many other surfaces are used as an alternative to the block or sandpaper. With this tool, surfaces can be sanded very well. The reason for this lies in the very solid core, which offers enough resistance to guarantee a very satisfactory result. The flexible surface adapts perfectly to different structures.

Where are abrasive fleece & abrasive sponges used?

Surfaces can of course also be roughened or matted with this tool. Depending on which material is to be processed, different grain sizes are required. The standard version of the grinding pad consists of aluminum oxide with a ceramic coating. Medium-coarse grains are suitable for the first steps, sanding sponges for wood usually work with this grain. There is also abrasive fleece for tiles, car paint and metal. A 150 grit is provided to sand off paint residues. 180 to 220 grit are used to remove scratches in the Wood.

The quality determines the longevity!

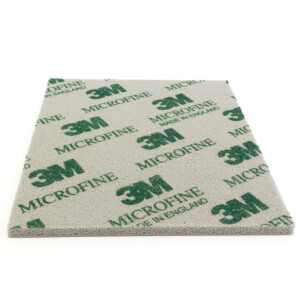

This tool is a heavy worker in constant use! It is therefore important to look for quality when buying. This depends primarily on the strength of the core, the flexibility of the surface and the coating. In almost all test comparisons, the 3M sanding pad performed best and impressed with an excellent price-performance Ratio!

Why do 3M abrasive pads perform so well in all comparisons?

These sanding sponges are characterized by their high quality and workmanship. In addition, they are extremely durable and robust. This tool is a cost-effective variant for both dry and wet sanding and is suitable for sanding plastic, wood, metal, car paint and plaster.

What makes sanding pads so Special?

Sanding pads can be used for both wet and dry sanding. The core of the sanding sponges is very absorbent. Its flexible nature enables good ergonomic work. The strength makes it easier to work in difficult places. This is why this tool is preferred for machining edges and Corners.

Tips and tricks for working with the sanding sponge!

The selection of the sanding pad is decisive for a good result. Which sponge is suitable for which material can be found in most hardware stores or on their websites. Another option is to try the tool in an inconspicuous place. Keeping the sponge clean is important for longevity. After the work is done, the sanding pad should therefore be thoroughly cleaned and dried.

The material "wood" is the most common. The grain must always run from coarse to fine. The cut itself should run like the wood grain. If you sand against the grain, sanding marks will become visible or the wood will be damaged. These errors take time and are often difficult to repair. The rough sanding is intended to remove varnish, grooves, scratches, dents or plane marks.

It is important that the workpiece is fixed (vice) before machining begins. If the grain is accidentally sanded, it can be touched up with an iron. To do this, a damp cloth (cotton) is placed over the area and ironed over it several times with an iron. As a result, the wood fibers swell and cracks, etc. are filled up again. Even after the rough dry sanding, it is advisable to moisten the wood with a cloth. This is how the fibers expand again. The remnants can be sanded off in the middle sanding.

Above all, wood that is later exposed to moisture and moisture should be treated in this way. The wood should be well soaked, but not "float" (damp tea towel, flower sprayer). Sanding sponges are particularly suitable for profiled and curved wood as well as grooves.