Transfer Tapes

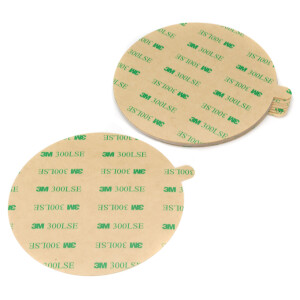

We carry a large range of high-quality adhesive transfer tapes from well-known manufacturers such as 3M. We have these made as rolls and pads in various sizes.

Are you looking for transfer tape? Then you are exactly right here!

After many years of development, based on experience in adhesive technology, 3M has brought out high-quality adhesive transfer tapes with a particularly strong instant adhesive effect and extremely solid final adhesion for the industry.

Transfer tape by 3M

With 467MP, 468MP, 9495LE and 966 3M has developed tapes / adhesives (without backing) especially for industry. These are AGA and UL recognized and meet the FMI requirements of the military and the automotive industry.

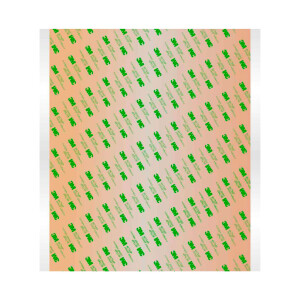

The special acrylate adhesive film guarantees a lasting adhesive effect even on smooth, heavily used, painted, or treated surfaces and adheres to glass, metal, plastic, ABS, PVC or rubber.

Areas of application for adhesive transfer tape

The double-sided adhesive tape is particularly popular with hobbyists: sticking the mobile phone / tablet display becomes a relaxed affair with the adhesive tape without a carrier. High-quality high-tech devices such as cell phones and tablets are spared any surface damage with the solvent-free LE 300 LSE adhesive.

Due to the small thickness of the adhesive tape, the gap dimensions are not increased unintentionally. Our customers use the transfer tape for sticking touchscreens on mobile phones and tablet PCs from all well-known manufacturers. The waterproof and UV-resistant adhesive tape can not only be used for electronic devices, but above all in the household, in the automotive and aircraft sectors or even in the medical sector. This makes it easy and efficient to create a self-adhesive holder for signs or back-printed front panels, but also labels, etc. |

Due to the excellent adhesive strength and resistance, the products of the adhesive series 300 LSE can be classified as permanent, low-temperature and special adhesives (PNS) (according to DIN 30646). The adhesive transfer tape can be cut to the desired size and shape with normal scissors.

In addition, the adhesive residue can be completely removed without leaving any residue.

Advantages of 3M transfer adhesive

- high resistance to moisture

- Insensitive to temperature fluctuations

- Resistant to chemical influences

- Flexibility

- Compensation of surface roughness

Transfer adhesive features

Relative humidity: High relative humidity does not affect the adhesive's performance. The bond values are generally higher after exposure to 90% relative humidity for 7 days at a constant temperature of + 32 ° C than at the beginning of the bond. Resistance to water: 100 hours of storage of the adhesive bond in water at + 22 ° C does not lead to any change in the adhesive values. Permanent temperature resistance: The transfer adhesive can be subjected to permanent loads from - 40 ° C to + 95 ° C; for a short time (up to 1 hour), the adhesive connection can be subjected to loads of up to + 150 ° C. Resistance to temperature changes: The adhesive values generally increased when the following temperature change cycle was carried out four times: 4 hours + 70 ° C; 4 hours - 29 ° C; 16 hours + 22 ° C. Chemical resistance: When properly bonded, the adhesive connections are resistant to most mineral oils, greases, fuels, aliphatic solvents, weak acids, salts, and alkalis, such as gasoline, kerosene, JP-4fuel, lubricating grease, etc. |

Adhesive tapes without a backing are suitable for:

High energy surfaces:

- Metal

- Steele

- Aluminum

- Glass

- Plastics (PVC, ABS, Polycarbonate, or acrylic glass)

Low energy surfaces:

- Polyethylen

- Polypropylen

- Wood

- Natural rubber

- Nordel

- Buna-EP

- Vistalin

- Keltan

- Elvax

- Hostalen

- Lupolen

- Elastosil

- Perbunan

- Amite A

This makes the adhesive very suitable for touchscreens, digitizers, glass panes or mobile phone displays. The low-energy surfaces in particular pose a major challenge for most adhesive tapes. This is where most conventional adhesive tapes fail. The adhesive tape was developed precisely for this area to firmly bond the workpieces with a high initial tack and permanent adhesive force.

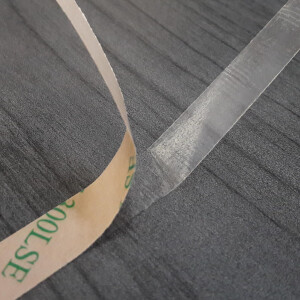

Instructions for using transfer tape

Before you use the adhesive tape, it must be ensured that the bonding surface is free of dust, grease and completely dry. A standard glass cleaner is suitable for this. In stubborn cases, benzene or isopropanol can be used. The required pieces of tape are now cut to size from the roll of adhesive transfer tape. Now the transfer tape can be applied to the desired surface. Apply firm pressure several times over the adhesive tape so that the acrylate adhesive completely covers the adhesive surface and prevents air inclusions. The protective paper can now be removed so that the workpiece can be glued to it. Any finger contact with the adhesive layer is to be avoided. A pair of tweezers can be used to make it easier to remove the protective paper from very small pieces. Now the workpiece can be attached. Then the connecting pieces should be pressed firmly again. The heating of the adhesive points by applying heat with a hair dryer accelerates the achievement of the final adhesive effect. |

Instructions for replacing and sticking the mobile phone display

- Remove the old cell phone glass / thoroughly clean the surface to be glued

- Cut the transfer tape to size and attach it

- remove the protective paper

- Attach the new cell phone glass and connect it with pressure

- Accelerate the adhesive action with heat

Further areas of application:

- Digitizer

- Suitable for electronics, household, medicine, motor vehicles and aircraft.

- Self-adhesive finishing of signs, back-printed front panels, labels, etc.

- Connect the touchscreen display to the housing

- Especially on low-energy surfaces, such as B. Polyethylene and polypropylene Bonding foam and powder coatings

Removing the transfer tape

Since the tape is very sensitive to the peel force, this is the best method to remove the tape again. Take a corner or edge of the glue point and start lifting the transfer tape with your fingernail from there. In stubborn cases, a pocketknife or tweezers can be used to lift. Warming it up with a hair dryer makes it easier to remove the tape.

Storage

The transfer tape should best be stored in a polybag in a cool, dry place protected from the sun (at +22 ° C and 50% relative humidity).