Double-sided tape

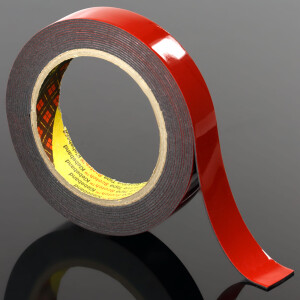

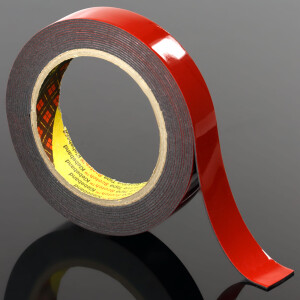

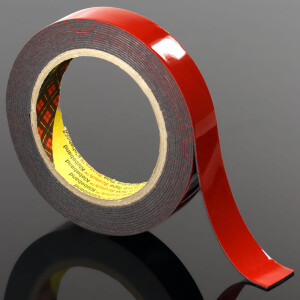

As a specialist in high-quality adhesive products, we offer you a large and constantly growing range of double-sided adhesive tapes for a wide variety of applications. Trust on quality products from well-known brands such as 3M, Tesa and Orafol, as well as the products of our own brand Dondo.

Regardless of whether you want to glue large areas quickly, are looking for a weather-resistant adhesive tape for outdoor use or want an extra strong hold on surfaces that are difficult to bond: In the large range on Dondo.de you will find a double-sided adhesive tape that meets your requirements. Try it!

How does double-sided tape work?

Double-sided adhesive tape is adhesive tape that has adhesive on both sides. They offer countless possible uses and have fixed tasks in many industrial sectors. In the automotive industry, for example, emblems, moldings, sills, spoilers and other attachments are assembled with double-sided adhesive tape. Double-sided adhesive tape is very often used when laying floor coverings such as carpets, but also to make signage. For these examples, however, you cannot use any random adhesive tape, but rather a double-sided adhesive tape with appropriate properties should be selected.

The adhesive tapes obtain their special properties from the carrier material, the material where the adhesive is applied, as well as from the adhesive applied. An exception are adhesive transfer tapes, which are pure adhesive between two protective films without a central carrier.

Our range of double-sided adhesive tapes

We have put together a selection of double-sided adhesive tapes from our range and listed them according to their special properties and possible applications. These are examples for illustration purposes, the actual possibilities in the use of our products are many more numerous. Let yourself be inspired.

For automotive vehicle add-on parts

| Discover our range of double-sided adhesive tapes with extra strong adhesive. These tapes consist of a 100% closed-cell acrylate adhesive, some of which have an additional adhesive on both sides. This makes it possible to combine different materials with one another in a very uncomplicated and permanent manner. You can find information on this in the respective product descriptions. We recommend for this area of application:1. 3M PT1100 - For bonding scratch-optimized paint systems and MSE substrates such as ABS. 2. Dondo ACR11-Pro - Very good adhesion to numerous materials, especially polyolefin. 3. 3M GT6012 - Very good adhesion to many automotive surfaces. |

For floor coverings

| Double-sided fabric adhesive tapes are ideal for tasks like this. The fabric backing gives the tapes flexibility and enables them to be used on uneven and rough surfaces. The adhesive used impresses with a high level of immediate adhesion and connects numerous materials reliably. We recommend for this area of application:1. Dondo Double-sided Carpet & Floor tape - Equipped with an extra strong acrylic dispersion adhesive, these products can be used on numerous materials. 2. 3M 9525 - This double-sided adhesive tape with a backing made of cellulose tissue impresses with a high level of immediate adhesion and is a very popular product, especially in trade fair construction. |

For transparent / translucent surfaces

| If you want to connect transparent materials with each other, it is very important that the connection is as invisible as possible. Our assortment is sure to include the right transparent double-sided adhesive tape. We recommend for this area of application:1. 3M 4905 - for materials with high and medium surface energy 2. Dondo Double-sided tape transparent & waterproof - for permanent hold even at high temperatures up to 93° C and humidity 3. 3M GPT-020F - for many high and low energy surfaces |

For rubber & other low-energy surfaces

| The double-sided Dondo-GTSK fleece tape is used reliably as foam lamination tape in the automotive and construction industries, for example. The acrylate adhesive used guarantees a very high level of immediate adhesion, especially on surfaces that are difficult to bond. |

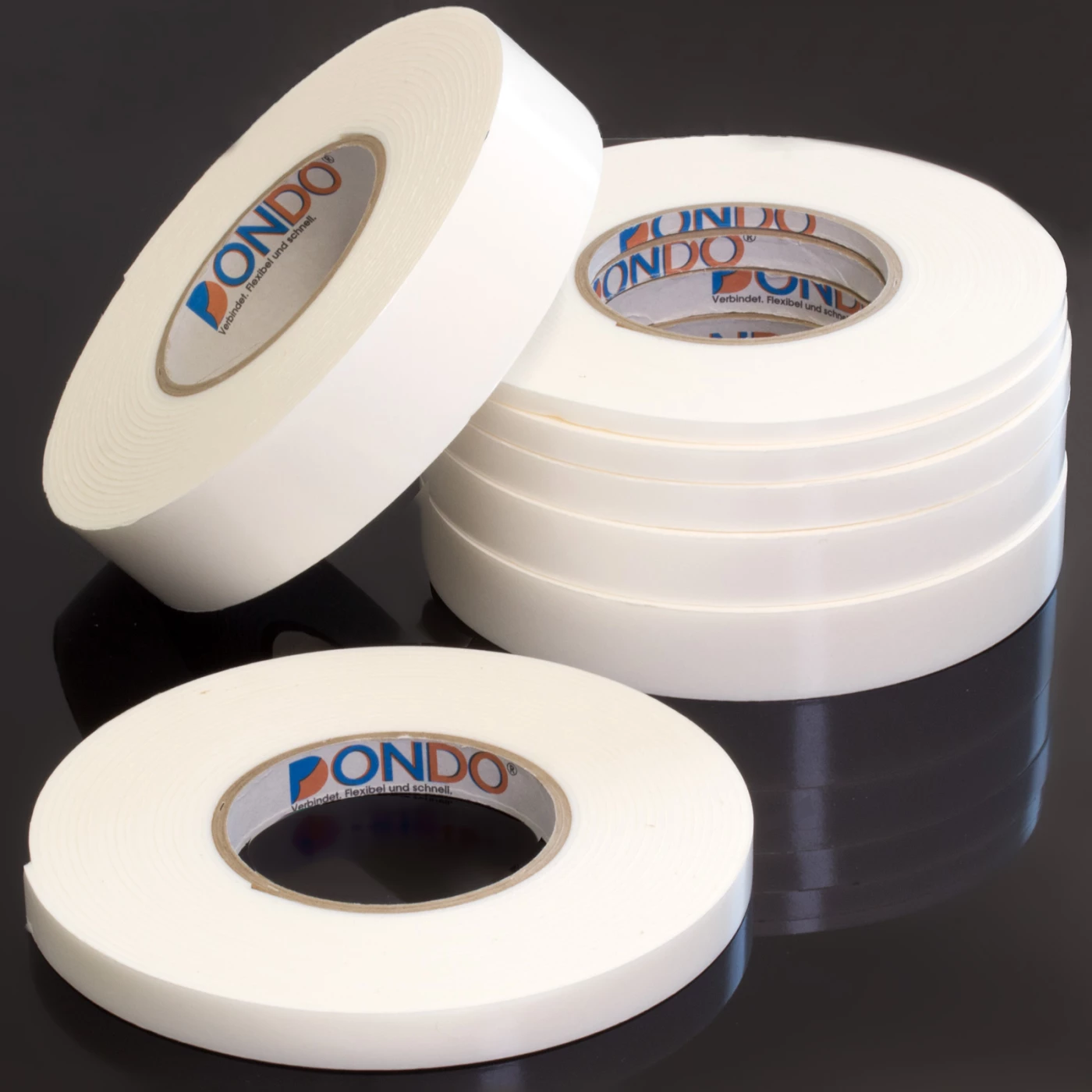

For mounting mirrors, signs or strips

| Double-sided foam adhesive tapes are the first choice for inconspicuous assembly without the hassle of drilling. They adhere to a wide variety of materials, level out surface unevenness and have sealing properties. We recommend for this area of application:1. Dondo Foam tape double-sided white - for bonding with larger surface unevenness in the interior 2. Dondo Foam tape double-sided black - the all-rounder for indoor and outdoor use 3. 3M 9528W - for permanent bonding indoors |

For increased operating temperatures - high temperature resistance

| The 3M VHB double-sided assembly tapes GPH-060GF and GPH-160GF are high-performance adhesive tapes with particularly high immediate adhesion, good sealing function, high adaptability and high temperature resistance. They can be exposed to loads of up to 150°C over a longer period (days, weeks) and even up to 230°C for a short time (minutes, hours). They are also perfect for multi-material connections of high and medium-energy surfaces. |

Make signs, labels and more self-adhesive

| The strapless variant - it is pure adhesive without a central carrier. The extremely small thickness of the adhesive transfer tapes enables an almost invisible connection. Our range of adhesive transfer tapes from 3M convinces with a particularly strong instant adhesive force and an industrial standard final adhesion. We recommend for this area of application:1. 3M 9495 LE - High immediate adhesion and shear strength even with materials with low surface energy / first-class performance on slightly oily and powder-coated surfaces. 2. 3M 966 - Specially developed for applications that require high temperature resistance and permanent adhesive strength. 3. 3M 468 MP - short-term temperature resistance of up to 200 ° C. Permanently up to 150°C. |

Why use double-sided tape?

You can leave drills and screws in the toolbox. The use of double-sided adhesive tape has numerous advantages and enables secure and long-term connections.

- invisible connection

- even stress distribution

- forces are evenly distributed

- Unevenness in material surfaces can be leveled out

- Combination of different thermal expansion coefficients possible

- Surface protection, as there is no risk of corrosion from drilling

- Weight reduction

- Sealing function

- quick and easy to use

Double-sided adhesive tape is as versatile as the different uses. Regardless of whether you want to use it to lay carpets, have discovered double-sided adhesive tape as a practical alternative to drilling or have very special requirements as a commercial customer: With the right product, your wishes can be put into practice.

What makes a good double-sided adhesive tape?

While commercial adhesive tape mostly relies on “all-purpose glue”, which bonds uncomplicated surfaces quickly and relatively firmly, a good double-sided adhesive tape offers you a lot more. Specialized adhesives and carrier materials ensure exactly the desired adhesive strength, from easily removable to extra strong. In addition, they offer you additional properties that make the double-sided adhesive tape particularly reliable and pleasant to use.

This includes:

- Very good adhesive features

- Very good rolling behavior

- Ease of workability

- Resistance to environmental influences

- Surface protection

- Can be used on rough surfaces

- Can be used indoors and outdoors

- high temperature resistance

- Water resistance

Which double-sided tape is right?

The agony of choice. In order to create a secure bond according to your ideas, the right double-sided adhesive tape must first be selected. Depending on where and how you want to use the double-sided adhesive tape, it must meet different requirements. For example, weather resistance is important for outdoor use. A double-sided adhesive tape that is UV-resistant, temperature-resistant and waterproof does not become brittle or yellow and does not attack the bonded surface. In other cases, for example when gluing on walls or floor coverings, you often work with uneven, rough surfaces. This requires an adhesive tape with a high degree of adaptability, for example through a fabric or foam carrier.

Which materials should be connected?

The properties of the surfaces to be bonded are particularly important for the bond strength. How well and with what a material can be bonded depends on the so-called surface energy. Put simply, this describes the wettability. In the case of a high-energy surface, the applied water runs; bonding is easy, because the surface is easy to wet. With a low-energy surface, on the other hand, round water droplets form, and bonding is rather difficult here. However, specialized adhesives that have a high adhesive force have now also been developed for such difficult-to-bond surfaces.

High-energy surfaces (such as metal, paint, glass or porcelain) generally offer adhesives better adhesion than medium-energy surfaces (such as wood, PVC, polyester or cement) and these in turn offer better adhesion than low-energy surfaces (such as rubber, silicone or natural rubber). |

On each of our product pages you will find three scales that show you at a glance how well the double-sided adhesive tape of your choice adheres to high, medium and low-energy surfaces. The most common materials are listed as examples. In this way you can quickly and easily see how well the selected double-sided adhesive tape is suitable for a wide variety of materials.

Tip: You can also use the practical filters in the shop. This way, you can easily restrict your product selection by surface area.

Surface nature

In principle, it is easier to glue a smooth surface than a rough or structured surface, because the adhesive tape can almost completely lie against the substrate. But there are also numerous solutions among our double-sided adhesive tapes for bonding on rough or structured surfaces. However, it must be ensured that the surfaces to be glued are free of dirt, dust or grease, only then can the adhesive completely wet the surface.

Tip: We recommend testing the surfaces to be bonded before each application for the compatibility of the adhesive and to assess whether the surfaces allow a connection. If possible, this test should be carried out under the real conditions of the planned connection. To do this, attach a strip of the selected double-sided adhesive tape to an inconspicuous place and peel it off again after a rest period of about 12 hours. |

Should the double-sided tape withstand any of the following loads?

- heat or cold

- temperature fluctuations

- UV radiation

- humidity

- mechanical stress

- static load

- chemical exposure

A look at the detailed description of the product shows you whether the selected adhesive tape is particularly suitable for this.

summarized: Whether narrow or wide, for smooth or rough surfaces, whether transparent or particularly temperature-resistant: In the product description you can see the most important information about the selected double-sided adhesive tape at a glance. In addition to the data on dimensions, bond strength and durability, you will also find additional information to help you choose the best double-sided adhesive tape for your needs:

|

Which double-sided tape is extra strong?

Depending on what you want to use the double-sided adhesive tape for, the greatest possible adhesive force is not everything for you. The time it takes for the adhesive used to develop its full adhesive strength can also be decisive for you.

For example, double-sided adhesive tape with acrylate adhesives can develop a very high final adhesive strength on suitable surfaces. Its insensitivity to stress, such as high temperature or UV radiation, make it a durable solution for many areas of application. However, acrylate often takes several hours or even days to develop its full adhesive strength. If you want to glue large areas quickly and reliably - for example in trade fair construction or when laying carpets - this can be a hindrance. In these cases, you need a double-sided adhesive tape with immediate adhesion and a high initial adhesive strength. For this purpose, adhesive systems use synthetic rubber, for example.

Can the double-sided adhesive tape be peeled off without leaving any residue?

While some adhesive tapes (often with acrylate adhesive for an extra strong hold, for example) adhere aggressively and create a permanent connection that can hardly be detached, there are certainly adhesive tapes that can be removed from the bonded surface without any visible damage to the adhesive - for example, to correct a faulty bond to correct. It is essential to use double-sided adhesive tape, which is recommended for the respective surface. For more information on removability and the period in which the product can be removed, see the product description.

Tips:

|

Process double-sided adhesive tape correctly

- Clean the surfaces to be bonded so that they are clean and free of grease. Lint-free cleaning cloths and special cleaning agents without moisturizing ingredients are suitable for this.

- Avoid touching the adhesive film if possible. Sometimes it is also advisable to wear suitable gloves - pay attention to the relevant information in the product description.

- Pay attention to the recommended gluing temperature. This is often between 18°C and 23°C but can vary depending on the product. This will prevent the adhesive performance from being impaired.

- Make sure that the contact pressure is even on the entire adhesive surface, particularly effortlessly using a squeegee as an aid, for example.

- For some adhesive applications with difficult surfaces, it may be advisable to use a primer that matches the adhesive.

In summary: the most important things brieflyWith double-sided adhesive tape, a reliably strong adhesive strength is usually important. This depends on the surfaces to be bonded, with smooth surfaces generally being easier to bond than rough ones. To make the perfect choice, however, it is worth taking a closer look: Which surfaces should be glued?Different surfaces require different adhesives for a strong bond due to their different surface energies. There are different adhesive tape recommendations for high, medium and low energy surfaces. What is the condition of the subsoil?Whether smooth, rough or porous: Depending on the structure of the surface, different types of carrier material are recommended. Fabric supports, for example, are particularly adaptable and very suitable for rough and uneven surfaces. Fleece and foam support can have insulating and vibration-damping properties. Does the double-sided tape have to adhere immediately?You can tell how high the immediate adhesion of a double-sided adhesive tape is by the initial adhesive force. Some products are extremely strong, develop their full adhesive effect, the final adhesive strength, but only after hours or days. Are there special loads or are special functions important?For specialized adhesive applications, a double-sided tape specially developed for this purpose is recommended. Professional quality products have a variety of special functions, from UV resistance and vibration damping to residue-free removal. |

You haven't found what you are looking for or would you like further advice?

We are happy to answer your questions and support you in finding the right product for your needs. Are you a commercial customer and need a double-sided adhesive tape with different dimensions for your daily use? Let us know so that we can find a suitable solution for you. We look forward to helping you.

You can reach us via:- Live-Chat - 7:30am -2:30pm (Mo-Fr)

- E-Mail ([email protected])

- Phone: (033971 / 302417)

- Fax: (033971 / 302419)